Corrosion: A Global Problem

Corrosion of reinforced steel in concrete is a global problem, but its deterioration rate is very high in the Arabian Gulf region because of the climatic conditions. Hence, the service life of reinforced concrete structures is significantly lower in the Middle East than in other parts of the world. Rehabilitation costs then get multiplied and the repair process becomes complicated.There is also a tendency to use a ‘trial and error’ approach to materials and processes which have not been standardized or fully tested as these processes are applied without supervision giving poor results.

Typical example of concrete degradation

Epoxy coated re-bars provide a comprehensive solution to the corrosion problem and Q-Coat has always been proactive in establishing the viability of epoxy coated re-bars and through a series of tests and experiments the conclusions drawn has advocated its significance for the industry.

Fusion Bonded Epoxy Coated Re-bars (FBECR)

When steel is exposed to moisture and oxygen, a corrosive coating is formed as rust, resulting in physical deterioration of the concrete structure, apparently visible as cracking, delamination and spalling. Also, the addition of chloride ions, such as in admixtures, deicing salts, chemicals or salt water can accelerates corrosion.

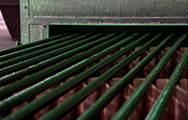

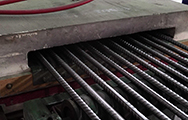

Epoxy coating is applied to reinforcing bars by fusion-bonding process. Fusion bonded epoxy coatings are 100% solid coatings applied as dry powders and formed into a film by heating. In use since mid-1950’s, advocates believe FBE offers sufficient protection to the steel substrate and is the ultimate in low volatile coatings since it contains no solvents. The coating is applied via electrostatic spray and provides corrosion protection to reinforcing steel and is considered as the most viable and cost-effective corrosion-protection system. Its greatest advantage lies in its applicability to the existing design without any changes in load capacity or section size, the only change is in the modification of development length.

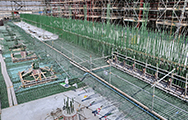

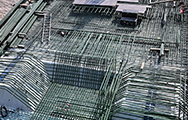

Usage of Fusion Bonded Epoxy Coated Re-bars